If you are concerned with the dimensions of the reamer you will be using to cut your next chamber, you need to understand more about prints. Like many things in life, people take some things for granted about chamber prints.

When I started out in gunsmithing in 1981 nobody ever pointed out what I am going to tell you here. In truth, I was totally ignorant of tolerances (like most of the shooting public). The industry standards saved my bacon until I understood more. I learned it the hard way, experience, mistakes, asking questions and lots of reading. I am blessed with a mechanical mind, so these concepts come easily to me. However, I have learned that there are many people who have to study hard to understand some mechanical concepts. My goal here is the demystify this subject.

The first thing you need to know is that there are three valid sets of prints for every cartridge.

- Chamber prints (larger than ammunition)

- Resize prints (for resize dies)

- Ammunition prints (smaller than chamber)

Why? Because they are all important and they are different from one another. We are going to discuss chamber prints for the sake of this discussion.

The first question you need to ask yourself is what information am I seeking?

- Are you comparing cartridges to decide which meets your desired use?

- Are you interested in specific measurements?

- Are you only looking for free bore length or neck diameter for specialty use?

- Did you just read on a forum or in an article that you should ask for a print?

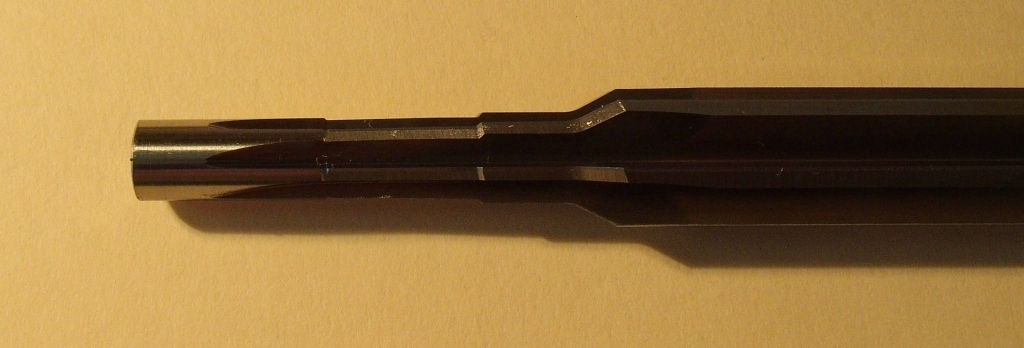

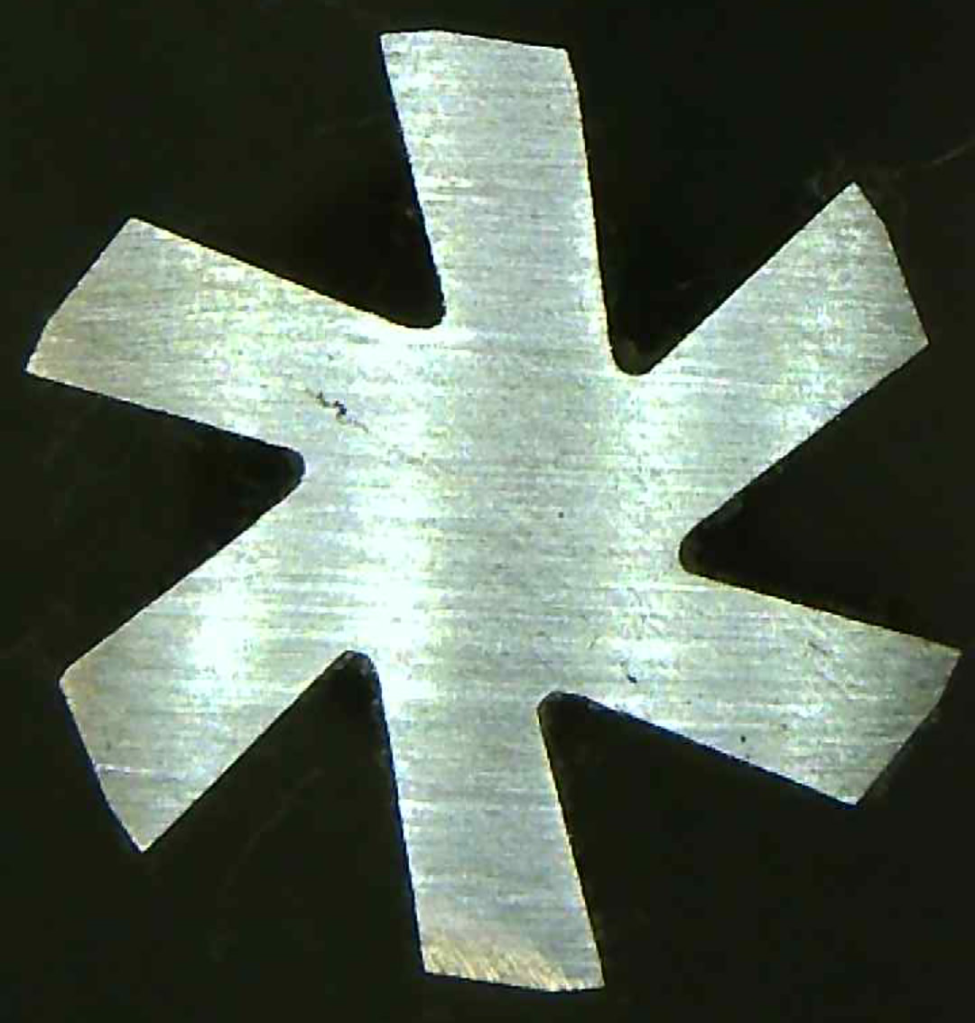

Chamber prints by their very definition are only a comparative tool. They represent the general specifications that reamer maker gives to their machinist and precision grinding personnel. The prints contain information about tolerances that are allowed during manufacturing of the tools.

Oh? you thought every tool was perfect? Sorry! That is not how the real-world works.

First, lets look at the chamber prints from SAAMI: The Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI) is an association of the nation’s leading manufacturers of firearms, ammunition and components. SAAMI was founded in 1926 at the request of the federal government and tasked with:

- Creating and publishing industry standards for safety, interchangeability, reliability and quality

- Coordinating technical data

- Promoting safe and responsible firearms use

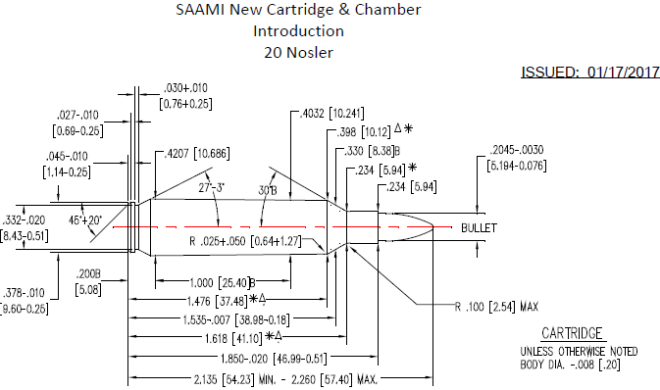

Below is the SAAMI chamber print for the 7mm PRC at the time it was introduced. Note on the right side of the print in bold “Chamber” this is the tolerance call out for SAAMI to the industry as a whole.

“ALL DIA”= how much are the factories allowed to vary on and diameter called out without further specifications. In this case it is plus .002” (2/1000) on any given measurement.

“Length Tol” = how much are the factories allowed to vary on the called our length measurements? In this case it is plus .015” (15/1000) on any given length.

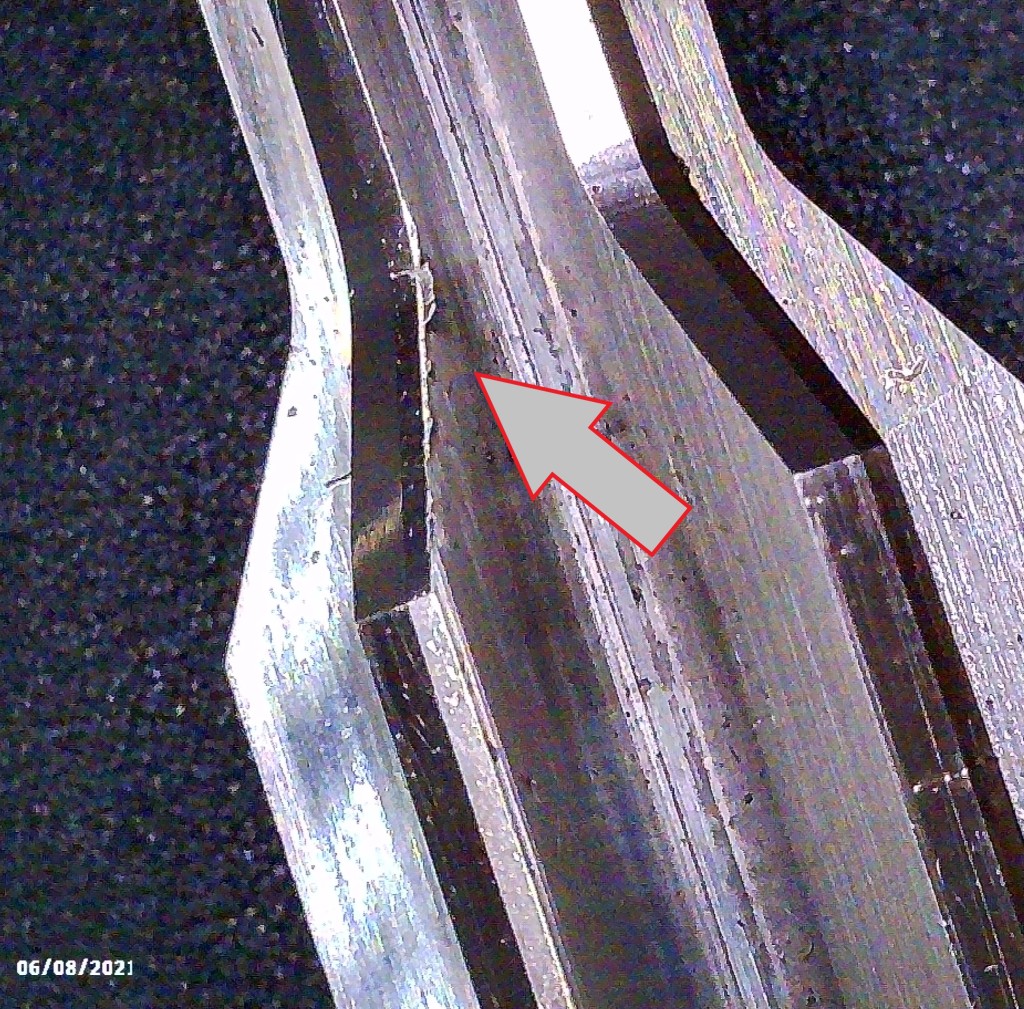

Reamer Manufacturers have to translate this information into manufacturing a quality product that the industry can rely upon. All makers have tolerances on their prints, I am not making comment on the size, measurement or value of any tolerance here. Only instructing you that it exists and you can look it up.

Note that on the print below the tolerances listed vary from SAAMI slightly. This is do to the real world application of standards to the manufacturing process. Also, reamer makers design the tools slightly under the absolute maximum dimensions indicated by SAAMI. This is because ammunition makers will tend to hold dimensions of ammo closer to the minimum end of allowed specifications. If you look at the ammunition dimensions published by SAAMI for the same cartridge you will notice a fairly large gap between minimum ammo and maximum chamber dimensions. This gap is used to insure reliability when ammo from company A is used in the chamber of a gun from company A, B, C or D.

Note that the reamer maker breaks the tolerances down even further.

- Two digit decimals are allowed to vary by .010” (10/1000) plus or minus.

- Three digit decimals can vary by .005” (5/1000) plus or minus.

- Those called out to four decimal places are held to .0005” (5/10,000) plus or minus

Now that you know about tolerances and where to seek them out; I will state that a chamber print only provides a concept of what the reamer will look like, not the actual dimensions of any given reamer. If that does not make sense, then you need to read this article over until it does.

This concept is not limited to firearms. These are long standing practices in the machining trade.

Let’s get to the reason you most likely asked for a print:

You want to know if the dimensions of the reamer in question are the dimensions you planned to use or match up to standards you have chosen to follow. I.E. available brass, reloading dies or projectiles you plan to use.

If that is what you seek, you have a few choices.

- Now that you understand tolerances as the apply to chamber reamers you can worry a lot less about the actual dimensions as long as they will work with your project.

- When you order reamers to purchase, simply request SAAMI or CIP standard tool where appropriate.

- If you are looking at a wildcat or some other design that is not standardized by these organizations then you will want a print to insure it matches your needs.

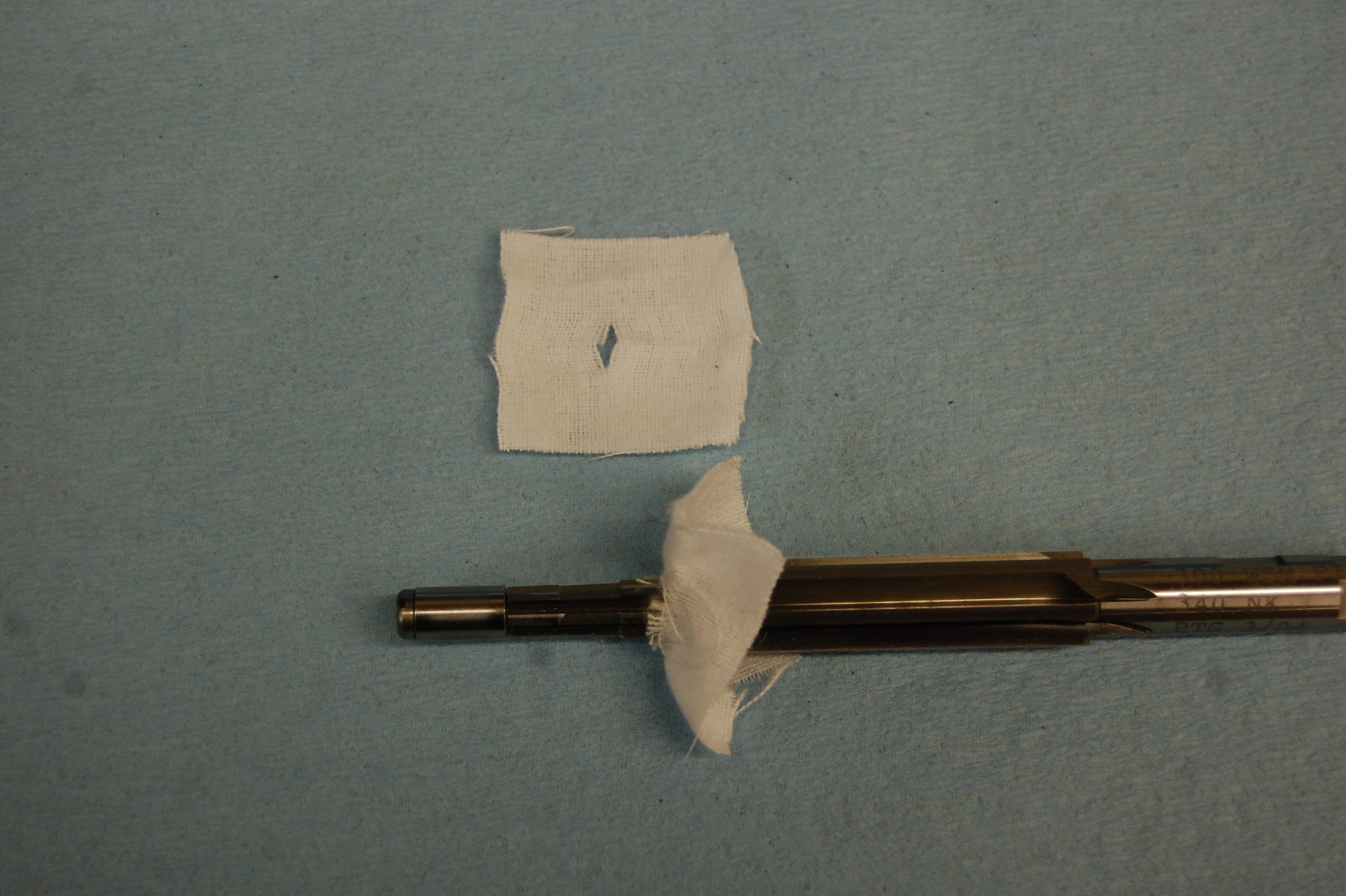

- You can trust the reamer maker to provide what you ask for (always double check what you receive from them).

- You can custom order your tools and pay in both time and money.

- You can spend a ton of money on CMM equipment to measure your tools.

- If you plan to rent a reamer you can request the actual measurements of the tool you will receive. This is really valuable if you are concerned about neck diameter or free bore. I recommend you check out 4D Reamer Rentals new offering, its just what you are looking for.

Before any of you decide to write me a nasty gram because you don’t believe tolerances are important, consider that you use headspace gauges when chambering a barrel. Why does that matter? Because they set the “tolerances allowed for chamber length”. So you use tolerances even when you do not realize it.

Keep learning, its fun and profitable.