Guest Blogger, Robart Schaefer

If you need to determine the bore diameter of a firearm, whether it be to get the exact  right size for cast bullets, or perhaps to identify the caliber, one of the best ways to do that is to slug the bore. This involves pushing a piece of lead, a slug, through the barrel and then measuring it. Usually, this requires a fair bit of pounding, especially if you do not have a slug that is close to the bore diameter. I have developed a method, however, that requires only a few light taps from a non-marring hammer and a standard cleaning rod.

right size for cast bullets, or perhaps to identify the caliber, one of the best ways to do that is to slug the bore. This involves pushing a piece of lead, a slug, through the barrel and then measuring it. Usually, this requires a fair bit of pounding, especially if you do not have a slug that is close to the bore diameter. I have developed a method, however, that requires only a few light taps from a non-marring hammer and a standard cleaning rod.

Most shooters are familiar with “rifled slugs” for shotguns like these from Remington: Most people believe, or assume, that the grooves on the outside of the slug are there to cause the projectile to spin, thus giving it stability. This is partly true, although it is a clever bit of marketing to give a helical shape to the grooves; they do little for stability. The stability comes from the center of gravity being in the front of the projectile, like a badminton birdie. The primary purpose of the grooves is to allow the slug to stay in contact with the inside of the bore, creating a tight seal and not destroying the barrel when it exits through the choke, the restriction at the muzzle of most shotguns. The grooves give the ridges a place to swag into without causing undue pressure.

So, “What does this have to do with the price of beer in Milwaukee?” you might ask. Well, I bought an old Swiss Vetterli rifle at a gun show, and I want to shoot it but, 10.4x38Rmm Swiss Vertterli rimfire is just about as rare

as hens’ teeth. With these archaic, and foreign, cartridges it can be difficult to find reliable information on them. In fact, this cartridge was dropped from Swiss military use before 1900 (that’s before the internet so there is literally no information on it). The lack of information is made worse by the fact that a lot of cartridges of this era were paper patched so many publications will list the bore size as the lead projectile size which is  absolutely incorrect because there would have been paper taking up the extra space in the bore.

absolutely incorrect because there would have been paper taking up the extra space in the bore.

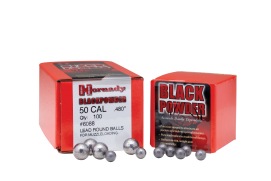

When I went to slug the bore of this rifle, I had no pure soft lead (recommended for this operation) that was close to the diameter; my only two choices were 36 and 45 caliber round balls. I was standing in my shop thinking how to make a 45 caliber ball smaller in diameter when I realized I didn’t even know how small to make it, and all I really wanted to do was make it easier to push through the bore. Well, this is how shotguns do it so it should work for my needs, too.

First, use a pair of pliers to form consistent grooves around the equator of the ball. (if you have trouble finding the equator, look in the tropics, where you can find bright red tourists, drinking out of coconuts). I used a pair of dial calipers to check the diameter was close enough to the bore diameter so that the ball would start into the muzzle of the gun.

Many types of lube will work for slugging, my favorite is Lucas Red n Tacky #2 grease. They use it in race cars, so you know its the right choice for an old black powder rifle. Place the ball in the muzzle being careful to keep it straight (this makes it easier to push through the bore).

Use a non-marring hammer to start the ball into the bore. You should only need a couple of light taps to get it started. This could be a done with a muzzle loading ball starter if you have one of an appropriate size. Then just push the ball through the bore. I used a 3/16″ brass rod, but a one piece cleaning rod would suffice. The force required is akin to seating a patched round ball in a muzzle loading rifle.

The slug came out with the ridges of the rifling clearly impressed into the grooves of the ball. The groove diameter of my rifle is .419″ and is has a bore diameter of .397″.

The slug came out with the ridges of the rifling clearly impressed into the grooves of the ball. The groove diameter of my rifle is .419″ and is has a bore diameter of .397″.